Why are there so many different saw blades?

The reasons for the wide range of different saw blades is due to the diversity of the materials to be sawn. It is crucial whether hard material such as iron, stainless steel, hardwood and tiles or soft material, such as softwood, chipboard, plastics or insulating material should be sawn.

Another factor is the desired cut quality. Whether a quick and rough cut is sufficient, or a clean, splinter-free surface cut is desired, whether angular accuracy or flexibility is necessary, or whether contours or curves are to be sawn, determines the selection of the correct saw blade.

The sum of the requirements decides which material the saw blade should consist of, which toothing, which blade thickness and blade height is the most suitable.

Flexible electron beam welded joint of hight temperature alloyed sprung steel to meet the highest demands.

für aluminium, metal and nf-metals

Alloyed steel with a diamond gritted cutting edge.

for glass, ceramic and fiberglass

Alloyed tool steel with tungsten carbide teeth or tungsten carbide gritted cutting edge.

for stainless steel, nf-metals or aerated concrete

Alloyed tool steel

for wood or plastic

High speed steel

for aluminum, metal and nf-Metals

Tips

zur richtigen Sägeblattwahl bei Säbelsägeblättern

for correct saw blade selection with saw blades

The tooth geometry and the tooth pitch which measures the distance of the tooth tips to one another determine the chip behavior and the saw progress. We recommend the use of fine-toothed blades in thin material and the use of coarse toothing in thick material.

Please note: 2-3 teeth should work permanently in the material.

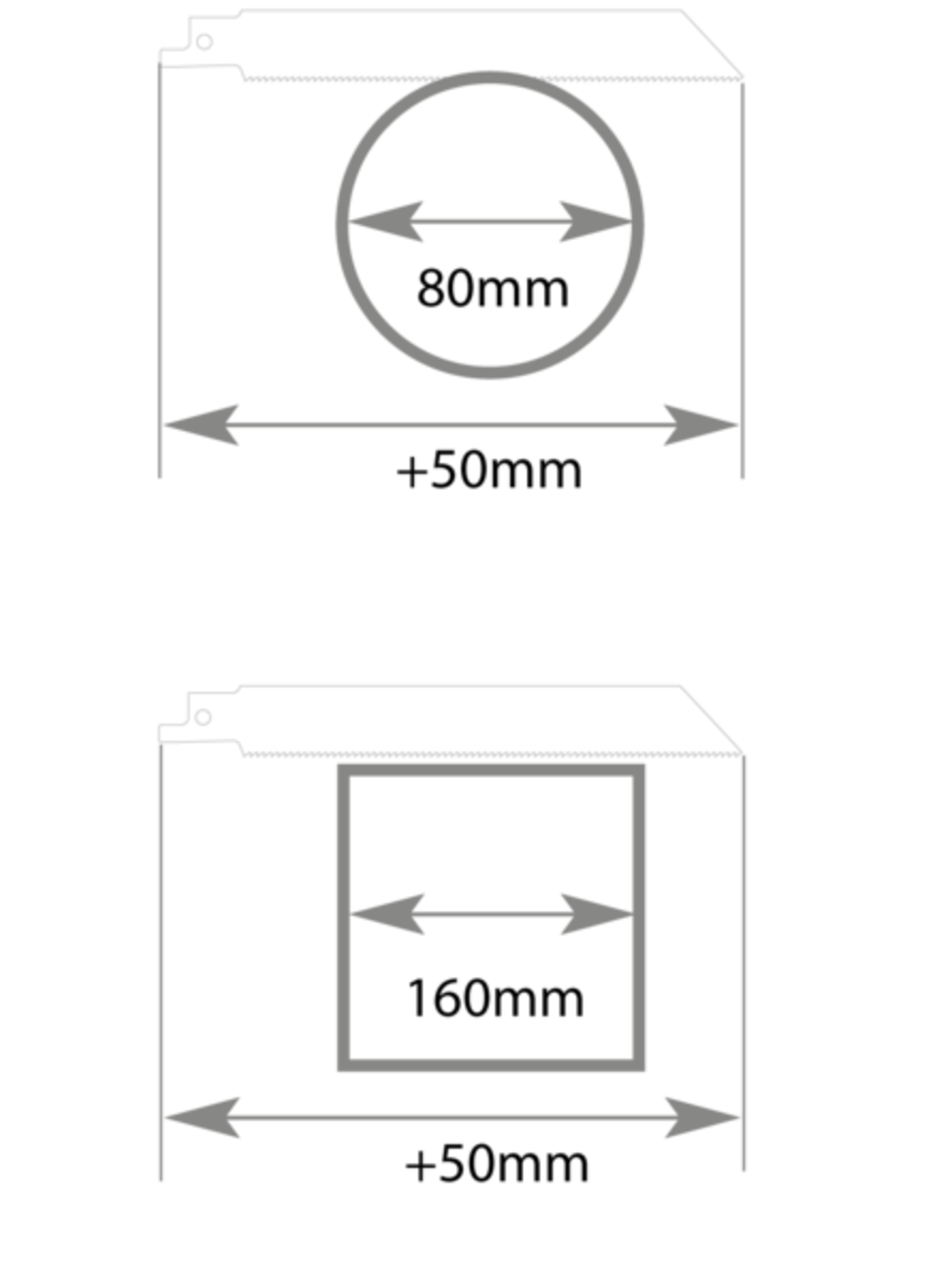

Width of material + 50mm = Length of blade

In order to increase the service life and wear resistance of the saw blade, it is recommended to use specific coolants such as:

- Cutting oil (steel, metals)

- Petroleum (aluminum)

- Water (plastics, plexiglas)